In 1994 Jo Paulides retires from the company. Sjaak Paulides becomes the new owner of Paulides B.V. New customers request ever more tailor-made products. Various new types of motors with permanent magnet excitation are designed and supplied to numerous applications, e.g. to industrial scrubbers and sweepers. From 1998 grandson Johan Paulides has been active in the factory. He is academically educated and adds to the engineering knowledge within Paulides B.V. This results in an ideal combination of engineering and practice.

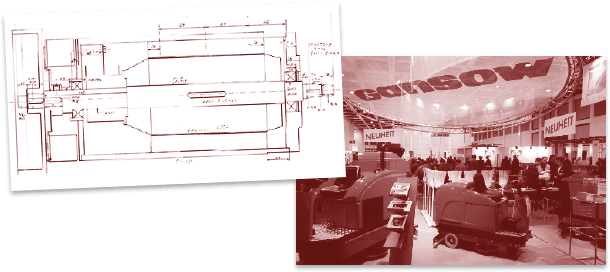

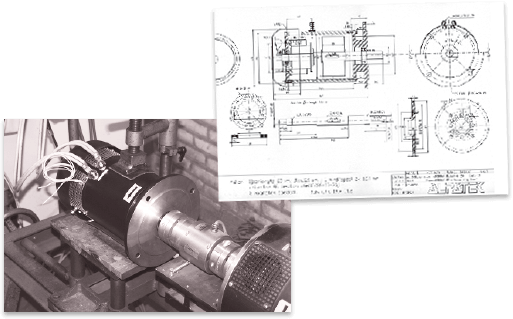

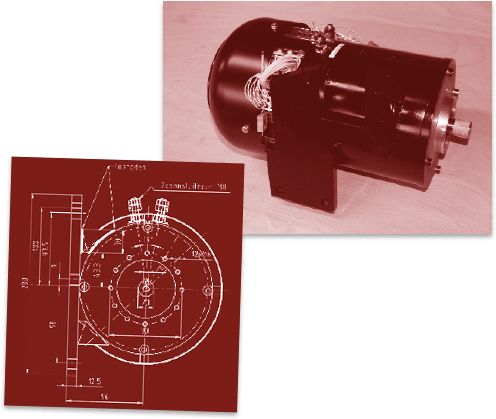

Hako industrial sweeper (type 36BHA09)

In the nineties a start was made with the design of a short drive system for a sweeping brush of Hako industrial cleaning machines (one of the globally leading companies of machine for in- and external cleaning). The sweeping brush drive unit was made in cooperation with Bockwoldt, where Paulides B.V. supplied the motor and Bockwoldt made the gearbox and assembled the system. To ensure a short drive, the motor end-plate was only assembled to test the machine in Paulides B.V., however, later removed to be replaced with the end-plate of the gearbox, where the shaft gearing and casing directly connected to the motor. This brushed DC motor was a compound machine of 0.8kW at 2300rpm. The motor is unique in that it contained four shunt coils and two series coils. The reason is that too little space was available for the shunt coils on the pole shoes, hence, the remaining shunt coil had to be integrated on top of the series coil.

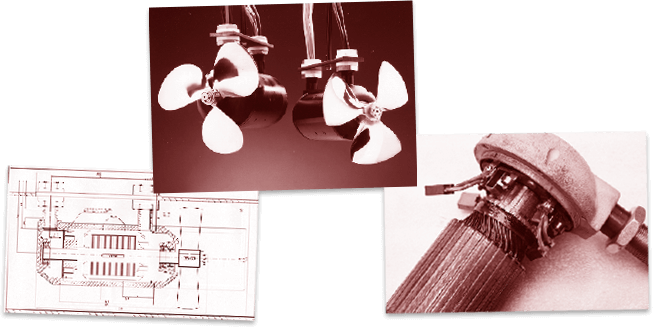

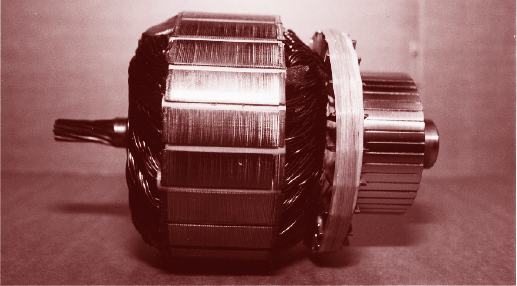

Tour boat motor (type 48PB8)

In 1994, a request was made from Hank in the "Biesbosch" for a battery supplied motor for a tour boat application, where solar panels were fitted on the roof to charge the batteries during the day. This challenge was accepted and a suitable motor was in-house designed and build. To much satisfaction a 48VDC, 8kW at 1500rpm motor was supplied. This force-cooled motor uses a series excited wound field and interpoles in series with the armature. Further, also the control (including a joystick and contactor) was supplied and installed. This motor has now been used for 14 years and, besides a few maintenance occasions, only a temperature controlled switched has been installed which ensures that the fan is not excited at low temperatures (less noise). For a new aluminium ship, the complete electrical system was supplied, i.e. the drive motor, bowthruster, solarpanels including electronics, contactors, joysticks, brushed DC controller and all this was installed on the boat.

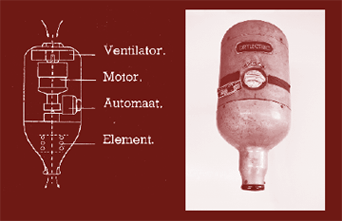

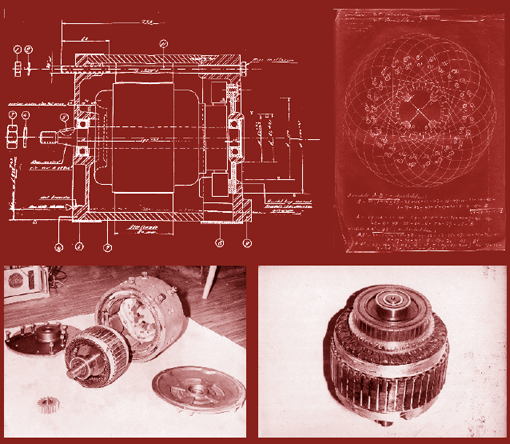

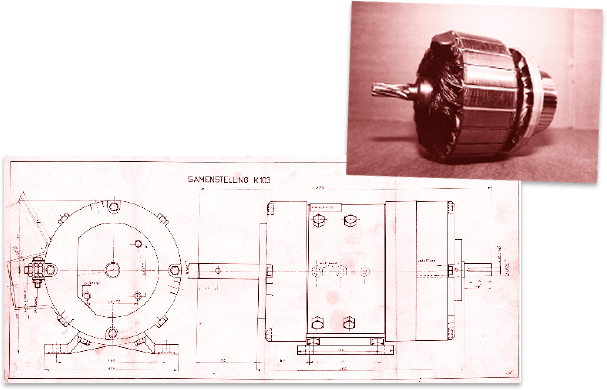

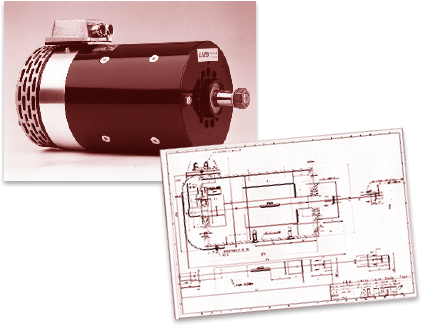

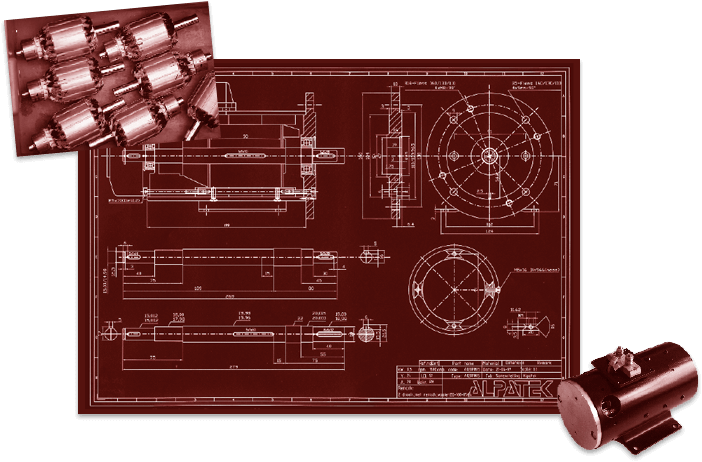

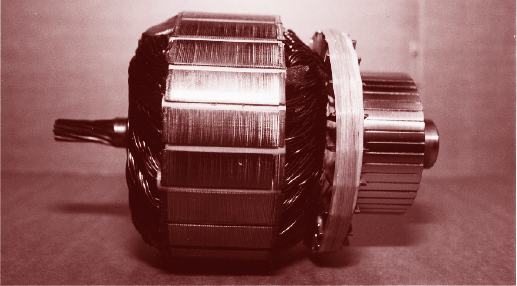

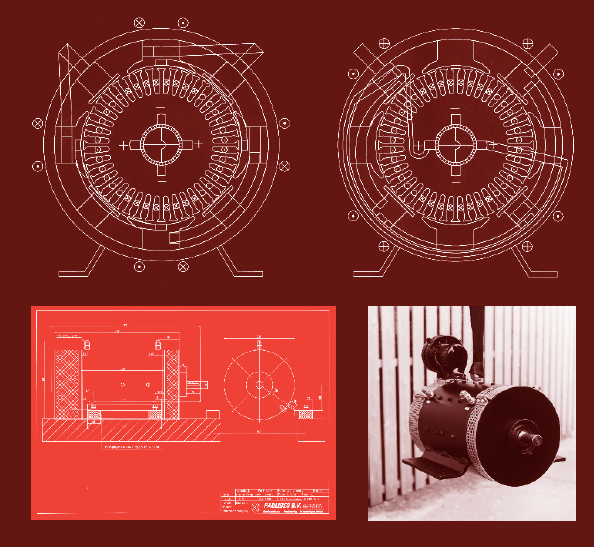

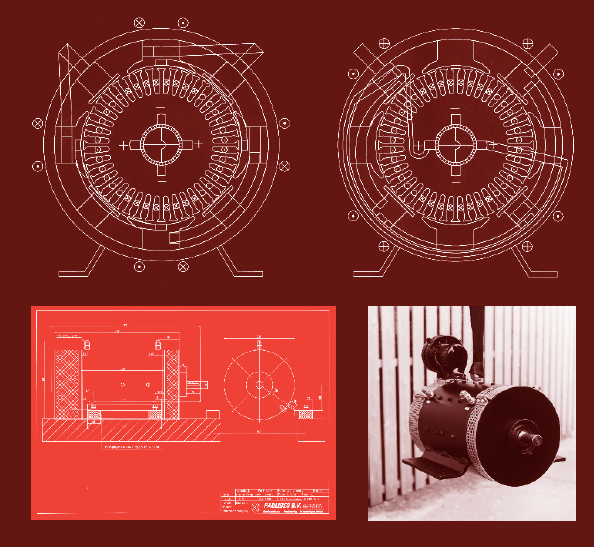

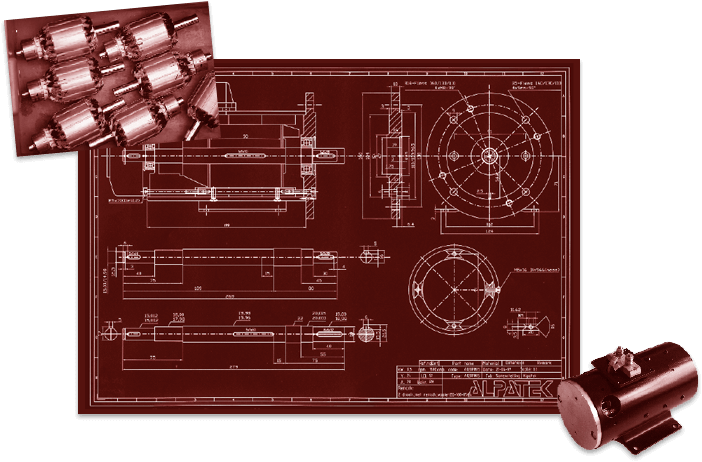

A120PM

In 1997 an increasing demand was made for a relatively small brushed DC motor. The designed was named the A120PM, which, by using a reduced number of slots, resulted in a very versatile motor. This motor is being used in numerous applications, e.g. movable swimming bath floors, airco units, traction, barrier systems, power steering, etc. Further, these motors are completely customer specific supplied with many available options, e.g. brake, fan, encoder, tacho, speed control, etc. This robust motor also combines the advantages of a reasonable price with an elevated power in a small volume.

Hide ▲